- sustainable manufacturing

- advanced automation

- efficient production processes

- reliable delivery services

years of experience

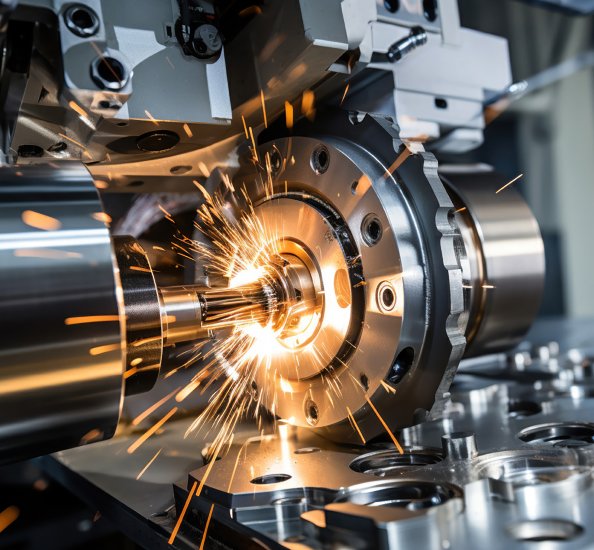

Incepted in the year 2014, we Mountain Forging has gained immense prominence over the years for its unmatched expertise in manufacturing high quality industrial fasteners. The company manufactures the widest range of precision Cold Forged Low and High Tensile Industrial Fasteners and components of Carbon, alloy and stainless steel well suited for all applications in every type of Industrial applications like various automobile usages, electronic engineering andconstruction industries along with their respective ancillaries.

We drive sustainable solutions in factory and industrial settings, focusing on efficiency, innovation, and environmental responsibility to support long-term growth.

To go global, set up higher bench marks of quality & Competitive Solutions to all precious Customers.

"To be known as the premier provider of innovative products for the engineering component marketplace & we believe that worldwide most of the Companies will drive into the future on Mountain Forging.

We strive to foster business and environmental growth through sustainable practices, innovation, and advanced technology.

Our process is designed to maximize efficiency and quality at every stage of production. By integrating advanced technologies and best practices, we ensure seamless workflows.

Chemical and Physical testing of each Raw Material as per the control plan concerning Raw Material Standards of purchased bright bars, forgings, castings & other assembly spares. Dimensional inspection of purchased bright bars, forgings, castings and other assembly spares.

Set up approval of manufacturing process as per defined control plan concerning drawing prepared. In-process inspection as per the defined control plan concerning drawings prepared on an hourly basis. Separate identification and traceability of non-conforming products at in process stage.

100% Visual inspection of each lot produced per defined plan concerning visual defects like operation missing, rusts, blow holes, rough finishing, dent marks, tool marks and input material defects. Sampling dimensional inspection of all critical dimensions per the defined control plan concerning the drawing prepared.

Pre-dispatch inspection before delivering the products to customers as per their requirements along with inspection report and separate identification of inspected samples concerning customer or internal drawing.